The whirring symphony of a brush cutter clearing dense undergrowth, weeds, and saplings is a familiar sound in landscaping, agriculture, and land management. But have you ever stopped to wonder about the intricate dance of mechanics that transforms electrical energy into such potent cutting power? The answer lies not just in the tool itself, but profoundly in the expertise and innovation driven by the electric brush cutter manufacturer. Understanding how these machines work reveals the crucial role these manufacturers play in bringing efficient, powerful, and increasingly eco-friendly solutions to challenging outdoor tasks.

The Core Principle: Converting Electricity into Rotational Force

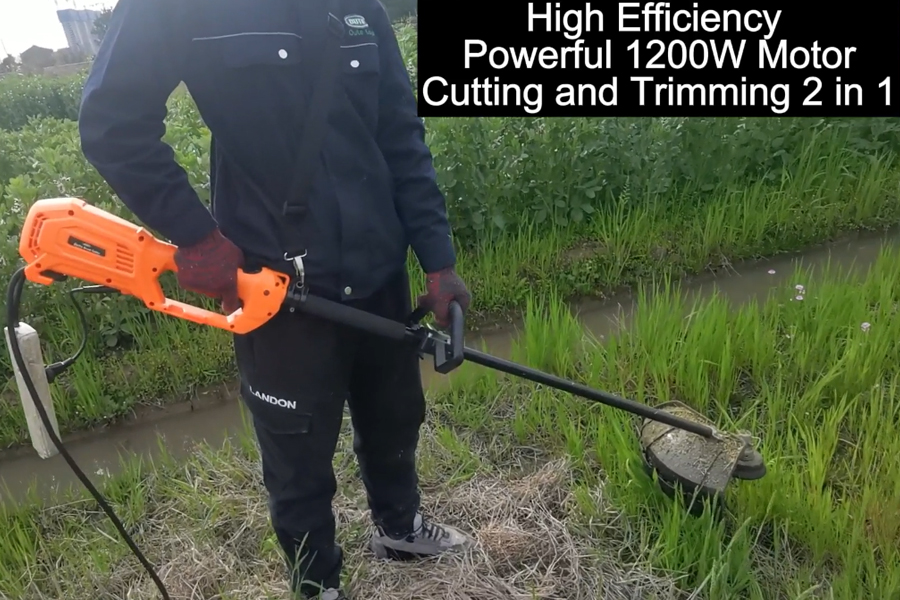

At its heart, an electric brush cutter operates on a relatively simple principle: converting electrical energy into high-speed rotational mechanical energy. This is the fundamental task every electric brush cutter manufacturer must master. Unlike their gasoline-powered counterparts, relying on internal combustion, electric models utilize an electric motor.

The Power Source: The journey begins with the power source. For corded models, this is straightforward – electricity flows directly from a mains outlet via a heavy-duty extension cord. For cordless models, the electric brush cutter manufacturer integrates high-capacity lithium-ion battery packs. These batteries store significant energy, which is delivered to the motor on demand. The choice and quality of battery technology are critical differentiators for any electric brush cutter manufacturer, impacting runtime, power output, and overall tool longevity.

The Electric Motor: This is the engine room. When the user triggers the safety switch and throttle (often a variable-speed trigger), electricity surges into the motor. Inside, electromagnetic fields interact with coils and a rotor, causing the central shaft to spin rapidly. The efficiency, power density (power output relative to size), and thermal management of this motor are paramount design focuses for the electric brush cutter manufacturer. Brushless DC (BLDC) motors are increasingly common, favored by the electric brush cutter manufacturer for their efficiency, longer lifespan, reduced maintenance (no brushes to wear out), and cooler operation compared to traditional brushed motors.

Transmitting the Power: Drive Shaft and Gearhead: The spinning motor shaft needs to transfer its energy to the cutting head, often located several feet away. This is achieved via a drive shaft running through the cutter's long shaft or tube. This shaft can be rigid (solid or hollow) or flexible (a spiral-wound cable within a tube). A responsible electric brush cutter manufacturer engineers this shaft for minimal power loss, high durability to resist torsion and impact, and user safety. At the end of the shaft, near the cutting head, sits a gearhead. This crucial component, meticulously designed by the electric brush cutter manufacturer, often incorporates bevel gears. Its job is to change the direction of the rotation (usually by 90 degrees) and sometimes to increase the torque (rotational force) delivered to the cutting attachment. The precision and robustness of this gearhead are vital for smooth operation and power transmission.

The Business End: Cutting Attachments

The rotational energy finally reaches its destination: the cutting attachment. This is where the electric brush cutter manufacturer provides versatility. Different attachments tackle different vegetation:

Monofilament Line (String Trimmer Head): Ideal for lighter grass, weeds, and delicate work near obstacles. The centrifugal force generated by the spinning head causes lengths of durable nylon line to extend stiffly outward, acting like tiny, fast-moving blades that slice through vegetation. The electric brush cutter manufacturer designs heads that allow easy line bump-feeding or automatic feeding.

Metal Blades: For thicker brush, saplings, woody stalks, and dense undergrowth, various metal blades are employed. Common types include:

Knife Blades (2-4 teeth): Good for coarse grass and light brush.

Saw Blades (40-80 teeth): Designed for cleaner cuts on thicker woody material and small saplings.

Circular Mulching Blades/Chipper Blades: Feature numerous small teeth to finely chop vegetation as it cuts.

Brush Knives/Blades: Robust, often 3 or 4-pointed blades designed specifically for heavy-duty brush clearing.

The electric brush cutter manufacturer must ensure the motor provides sufficient torque to spin these blades effectively without bogging down, especially when tackling tough material. Blade design, balance, and metallurgy are critical areas of expertise for the electric brush cutter manufacturer.

Control, Safety, and Ergonomics: The Manufacturer's Responsibility

A powerful machine is useless if it's unsafe or uncomfortable to operate. This is where the electric brush cutter manufacturer demonstrates its commitment to the user:

Safety Features: Essential elements include:

Handguards/Deflectors: Protect the operator from flying debris.

Deadman Switches: Immediately cut power if the operator releases the handle.

Shaft Collars: Prevent attachments from flying off during operation.

Vibration Dampening: Integrated into handles and shaft mounts to reduce operator fatigue and potential long-term injury. A conscientious electric brush cutter manufacturer invests heavily in R&D for vibration control.

Blade Brakes (sometimes): Some advanced models feature systems to stop the blade rapidly once the throttle is released.

Ergonomics: The electric brush cutter manufacturer designs harnesses, adjustable handles (loop, bicycle, or D-handles), and balances the entire tool to minimize operator strain during prolonged use. Lightweight construction, achievable partly due to the inherent efficiency of electric motors, is a significant advantage championed by the modern electric brush cutter manufacturer.

Controls: Intuitive throttle controls, easy attachment changing systems (like tap-and-go or screw-fit heads), and clear battery indicators (on cordless models) are hallmarks of a user-focused electric brush cutter manufacturer.

The Driving Force: Innovation from Electric Brush Cutter Manufacturers

The evolution of electric brush cutters is inextricably linked to the innovation driven by the electric brush cutter manufacturer. Key areas of focus include:

Battery Technology: Advancements in lithium-ion cells (energy density, charging speed, lifespan, cold-weather performance) are constantly pushed forward by the electric brush cutter manufacturer, enabling cordless models to rival gas power.

Brushless Motor Optimization: Maximizing power output, efficiency, and thermal management in BLDC motors is a core engineering challenge for the electric brush cutter manufacturer.

Smart Electronics: Some manufacturers integrate electronic controls for constant speed under load, soft start, and overload protection, enhancing performance and tool life.

Noise and Emission Reduction: A primary environmental benefit championed by the electric brush cutter manufacturer is drastically reduced noise pollution and zero direct emissions at the point of use.

Durability and Reliability: Building machines that withstand harsh conditions, impacts, dust, and moisture is fundamental for any reputable electric brush cutter manufacturer. Quality materials, sealing, and rigorous testing are non-negotiable.

Understanding how a brush cutter works – the flow of electricity into a motor, the transmission of rotation down a shaft, the redirection and potential torque amplification in the gearhead, culminating in the high-speed cutting action of line or blade – underscores the sophisticated engineering involved. Behind every efficient cut, every cleared path, and every quiet, emission-free operation stands the expertise of the electric brush cutter manufacturer.

It is the electric brush cutter manufacturer who selects and integrates the battery technology, designs and refines the motor and drive train, engineers robust and safe cutting attachments, and prioritizes user comfort and safety through ergonomic design. The shift towards powerful, reliable, and environmentally conscious land-clearing tools is being led by the relentless innovation of the electric brush cutter manufacturer. As battery technology continues its rapid ascent and motor efficiency improves, the solutions provided by the forward-thinking electric brush cutter manufacturer will only become more capable and essential, fundamentally changing how we manage vegetation across the globe. The next time you hear or see an electric brush cutter effortlessly tackling tough growth, remember the complex interplay of physics and engineering orchestrated by the dedicated electric brush cutter manufacturer.